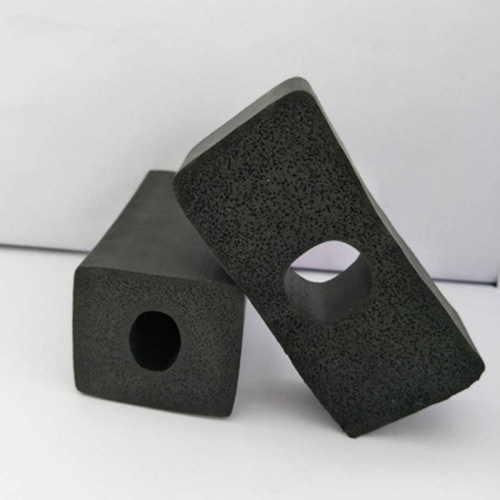

Customized Sponge Rubber Seals Extrusion for Industry Equipment

Review

Description

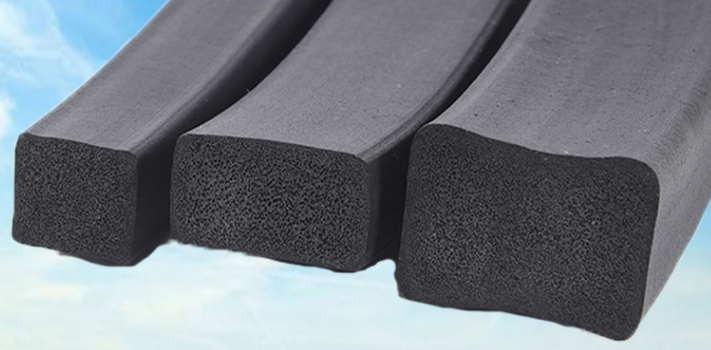

Sponge rubber strip plays a crucial part in sealing gap

throughout a multitude of different industrial sectors.

it seals against any ingress of water or air. Sponge strip have a closed cell structure,

therefore don't allow liquid, gases or air to pass through them.

Material: EPDM

Color: Black

Hardness:10~40ShA

Size: according to your requirement

OEM: Available

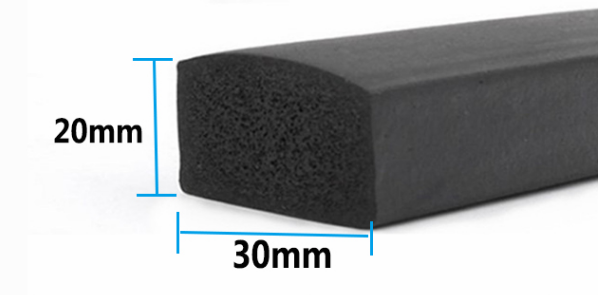

The Details of EPDM sponge/foam rubber strips

1. EPDM Rubber sealing strip,uniform foam , hardness with 15 Sha~20 Sha

Soft and spring back , Non-toxic,tasteless and durable

The surface is smooth, the foam density is even, the good surface is not sticky,

the permeability is good

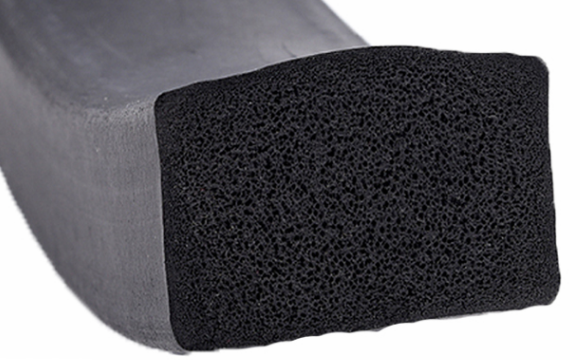

2.High temperature and wear resistance, difficult to deform

EPDM rubber can be used under-30 ℃ -120 ℃ for a long time without performance change

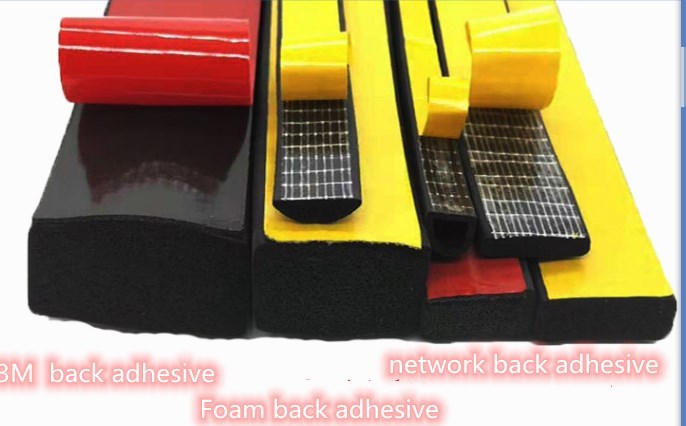

3.Various back adhesives can beaded on the back

3M back Adhesive, Foam back adhesive, network back Adhesive

The feature of EPDM Sponge /foam rubber sealing strip

1. Stable performance - acid resistance, alkali resistance

The chemical property is stable, except strong base, hydrofluoric acid,

does not react with any substance

2. EPDM foam strips are used in a variety of environments

EPDM rubber foam strips are not affected by ozone

and their physical properties only change slightly over time under ultraviolet

and other climatic conditions

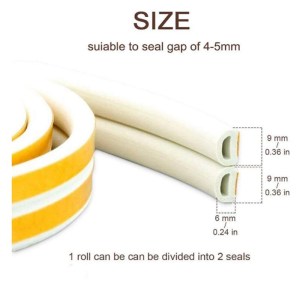

Installation:

1. Clean the surface before sticking;

2. Peel off the release paper backing section-by-section;

3. Stick on the surface place, then press.

The function of EPDM Sponge/foam rubber sealing strip

good sealing feature, stop water, smoke,light, insect, oil, air, dust inside. Good shock-proof,

sound proof, heat insulation ,ozone resistant, and Highly elastic, durable.

Application:

Building door & windows; curtain walls,Automobiles, trucks, boat, railway, plane, cabinet, bridge,

equipment,industrial and agriculture machines etc.